Insulating materials / Engineering plastics

Paper Sheet with Phenolic Resin

paper phenolic sheet is a high strength composite made by impregnating phenolic resin into layers of paper. It is strong and stiff, with excellent creep resistance and outstanding dimensional stability. Have machined into fabricated parts .

Phenolic Cotton Cloth Laminated Sheets & rods

Electrotechnical sheet textolite or Phenolic Cotton Cloth Laminated Sheets is a laminated material made by hot pressing of cotton cloths impregnated with a thermosetting phenol-formaldehyde-based binder.

Due to the use of cotton cloths, the phenolic cotton cloth mixture has high compression strength and increased resilience, favorably lends itself to machining by drilling, cutting and forging. That is why the phenolic epoxy resin cotton cloth laminated sheets are widely used to make parts loaded with reversed electrical and mechanical stresses or working under friction (bushings, cams, etc.).

Epoxy Fiberglass rod & Sheet

Fiberglass epoxy sheet is a popular and versatile high-pressure thermoset plastic laminate grade with good strength to weight ratios. With near zero water absorption, Fiber Glass Epoxy is most commonly used as an electrical insulator possessing considerable mechanical strength. The material is known to retain its high mechanical values and electrical insulating qualities in both dry and humid conditions. These attributes, along with good fabrication characteristics, lend utility to this grade for a wide variety of electrical and mechanical applications.

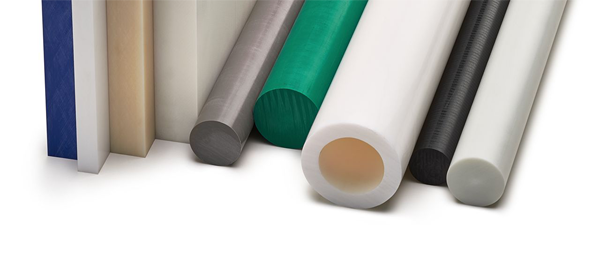

PVC rod

Polyvinyl chloride (PVC) or “vinyl” is usually an amorphous thermoplastic material with excellent chemical resistance and dielectric properties, good tensile, flexural and mechanical strength, low moisture absorption, exceptional dimensional stability and good flammability characteristics.

Nylon PA6 rod & Sheets

The PA6 plate is also known as Cast Nylon, which is generally superior to extruded Nylon-6. The Cast Nylon is the result of a new technology in Plastics, which makes available to you any shape or size. Guangzhou Ning E-plastics Co.Ltd is a genuine manufacturer of PA6 plates and sheets for all types of applications.

The PA6 plates show great protection from a wide cluster of chemicals including, salts, weaken acids and oxidizing operators which make numerous metallic fizzle. Additionally, it likewise offers high effect protection, high protection from fragility and disintegration, high warmth contortion temperature, vibration protection, and machinability make it the ideal material for some applications. Since it is made by coordinate polymerization of caprolactam, the polymer has never been softened and in this way has been subjected to any warm corruption. Likewise, its sub-atomic weight (upto10, 00, 000) is a few creases higher than the sub-atomic weight of expelled nylon6 (30,000). Thus for Bearings, Gears and Structural applications. Polyamide Sheet has delighted in expanding accomplishment in setting bronze, metal, steel, and aluminum and additionally wood and elastic in designing applications.

Teflon PTFE sheet and Rod

Virgin PTFE (Teflon®) is a white, waxy feeling industrial plastic and has almost universal chemical resistance. It has useful electrical and mechanical properties. PTFE can be molded into solid rods, tubes and sheets for machining into finished components. Teflon® has excellent non stick properties, it has a surface to which no substance will adhere. It also has excellent UV resistance. As well as having the lowest coefficient of friction of any solid (0.05-0.08), PTFE has a very high upper temperature limit of 260°C. PTFE in its virgin form can be easily deformed by high loads and compressive forces. To minimize this, additives such as glass (usually creamy color), Bronze (usually brown color), Carbon (black color) are added prior to molding. PTFE can also be chemically etched on one surface to allow bonding to steel surfaces. Trent Plastics (Fabrications) Ltd can supply PTFE in Virgin, filled grade in Sheet, Rod and Tube form, as well as a full machining service

Mica Sheet

The Mica group represents 37 phyllosilicate minerals that have a layered or platy texture. The commercially important micas are muscovite and phlogopite. Mica’s possess perfect basal cleavage, allowing crystals to be split into very thin sheets that are tough and flexible. Mica sheets are also transparent to opaque, resilient, reflective, refractive, dielectric, chemically inert, insulating, lightweight, and hydrophilic. Mica also is stable when exposed to electricity, light, moisture, and extreme temperatures.

Because of their perfect cleavage, flexibility and elasticity, infusibility, low thermal and electrical conductivity, and high dielectric strength, muscovite and phlogopite have found widespread application throughout industry , commerce and household goods. Mica provides an outstanding combination of chemical, physical, electrical, thermal and mechanical properties which cannot found in any other insulating product.